Metal of the future

Magnesium is 75% lighter than steel, and 33% lighter than aluminum. To reach efficiency targets, it is estimated that by 2025, on average a 100 pounds of magnesium will be used in each vehicle.

Our Projects

[PROCESS AND PRODUCTION]

Magnesium Oxide (MgO) Plant

To produce 30,000 tpa of high purity MgO (>98.5%) and 33,000 tpa of high value amorphous silica using a proprietary process.

[FLAGSHIP PROJECT]

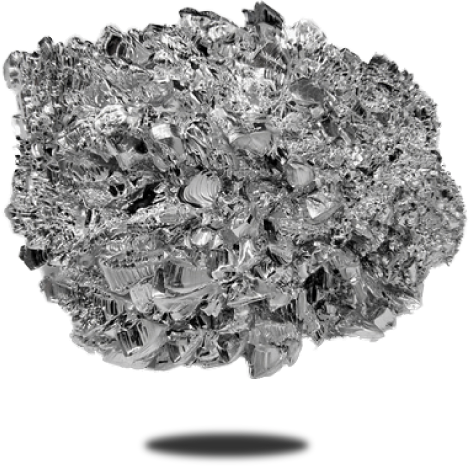

Magnesium (Mg) Metal Plant

To produce 5,000 tpa of Mg metal from an innovative approach to aluminothermic reduction of MgO.

[OUTPERFORMING SHEATHING]

MagBoard Products

To produce high performance MgO-based wallboards and Structural Insulated Sheathing (SIS) for building construction.

[ACQUISITION]

Magpower Fuel Cell

To offer reliable and efficient portable emergency power using ground-breaking Mg-Air technology.

WHY MAGNESIUM [Mg] ?

Low cost production and high profitability is achievable due to a large supply of low-cost tailings, optimum site locations, innovative technology and a focus on rapid commercialization through modular expansion and vertical product integration.

Automakers aim to decrease the weight without sacrificing strength. The use of Mg is increasing to improve fuel economy and mileage with the new USA EPA/CAFE emissions standards.

Mag One's process will produce a highly pure Mg with a low carbon footprint generating virtually zero waste.